Electronics & Microtechnology

Top Investment of the Year in Saarland

The place to be: the world’s largest and most modern factory for silicone carbide chips is being established in Germany’s Saarland.

Feb 02, 2024

Saarland is a master of transformation: this small state has always managed to adapt to radical change throughout its eventful history, and has frequently been the source of new developments. Today, Germany’s Saarland is a model region – including when it comes to handling structural change.

Its location in the south-west corner of Germany means that the French and Luxembourgish borders are just a stone’s throw away, opening up routes to promptly serve the markets in southern and western Europe. Companies in this area benefit from ideal access to European road networks, as well as to rail, air and water routes.

Wanted – and found in Saarland

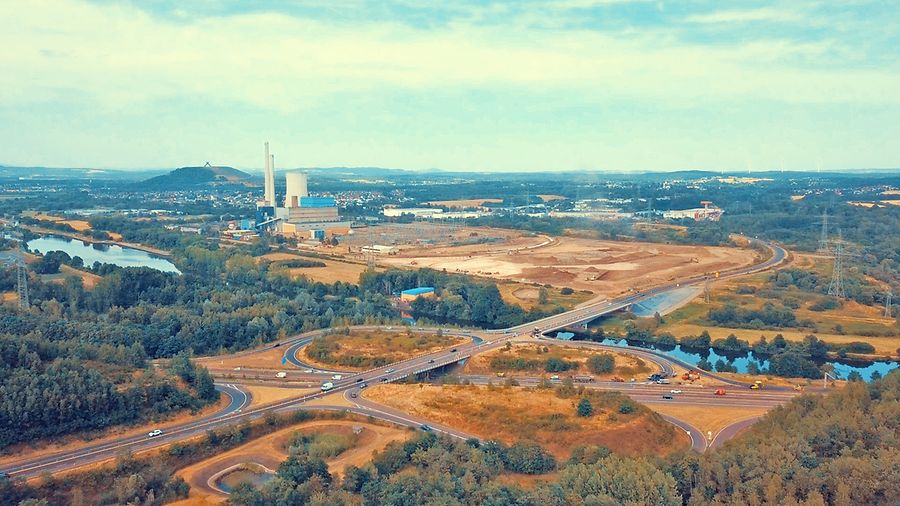

American chip manufacturer Wolfspeed made a hugely important investment decision after visiting the Saar: in the future, the group will be producing state-of-the-art silicon carbide chips on a former power plant site in Ensdorf (a twenty-minute drive from the state capital Saarbrücken). This product is particularly vital for the automotive industry and for energy production and supply.

When searching for a suitable site, the company ‘quite simply fell in love with Saarland’, Wolfspeed’s CEO Gregg Lowe explained when presenting the plans with Federal Chancellor Olaf Scholz and Federal Minister of Economic Affairs Robert Habeck in attendance. During their visit to the site of the future production facility in February 2023, they joined Minister-President of Saarland Anke Rehlinger and Saarland’s Minister of Economic Affairs Jürgen Barke to see for themselves how industry could be transformed in coming years. The highly qualified specialists available at this hub of automotive activity were another crucial factor in selecting the site. In addition to its location at the heart of Europe, the nearby river Saar also played a vital role – ideal for meeting the very high cooling water requirements of chip production. Furthermore, Ensdorf has an onsite substation (which is similarly receiving investment for upgrade works), ensuring optimum energy supply in all directions.

The project could ultimately create up to 1000 jobs. And others might later follow – for example, if new companies (such as subcontractors) also move to the area.

The project is part of the ‘Microelectronics and Communication Technologies’ IPCEI (Important Project of Common European Interest), coordinated at European level by the Federal Ministry of Economic Affairs and Climate Action and assigned funding within the federal budget. The total investment will amount to around 2.5 billion euros, with support from the EU, federal government and state government.

The ZF Group, currently the largest employer in Saarland, is also involved in Wolfspeed and the project. According to Minister-President Rehlinger, ‘Wolfspeed’s arrival and the ZF Group’s decision to make Saarbrücken its primary site for electromobility mark a new awakening that will be groundbreaking for the future of our state’. In Federal Chancellor Scholz’s view, ‘ZF's and Wolfspeed’s production plant for state-of-the-art semiconductors is making a significant contribution to securing supply for German and European industry. This project highlights Germany’s ability to compete, increases the resilience of our industry, and represents successful structural change.’

Wolfspeed, based in Durham in northern North Carolina, is a key player on the growing silicon carbide chip market. Founded in 1987, the company employs around 3500 employees at 15 locations across nine countries. The group focuses on developing and manufacturing silicon-carbide-based semiconductor components for high-performance applications. Its product portfolio includes semiconductor chips for energy and high frequency applications such as transport, electricity supply, inverters and wireless systems.

gwSaar paving the way

Development work at the brownfield site where the former coal-fired power plant once stood is in full swing. The establishment and development of the Ensdorf site is being overseen by gwSaar Saarland Economic Promotion Corporation, whose experts have diligently planned the project from start to finish.

Alongside the usual construction activities, such as infrastructure work on the site itself as well as a new link to the B269 national highway, there are various particularities that make this a particularly challenging construction site. These include the varying ground conditions, the danger posed by hidden World War munitions, a stream that needs to be relocated and run beneath the national highway, and the requirement to ensure completely vibration-free foundations for chip production at the plant.

The 6000 boreholes required to confirm that the construction site is free of unexploded ordinance have already been drilled. Only then can the 2000 piles be installed, which will form the base for the factory’s extremely heavy concrete floor slab.

All in all, a very complex task. Saarland is therefore paving the way for a project that will promote the country of Germany as a hub of microelectronics.