Markets Germany Magazine 3-2025 | Recycling

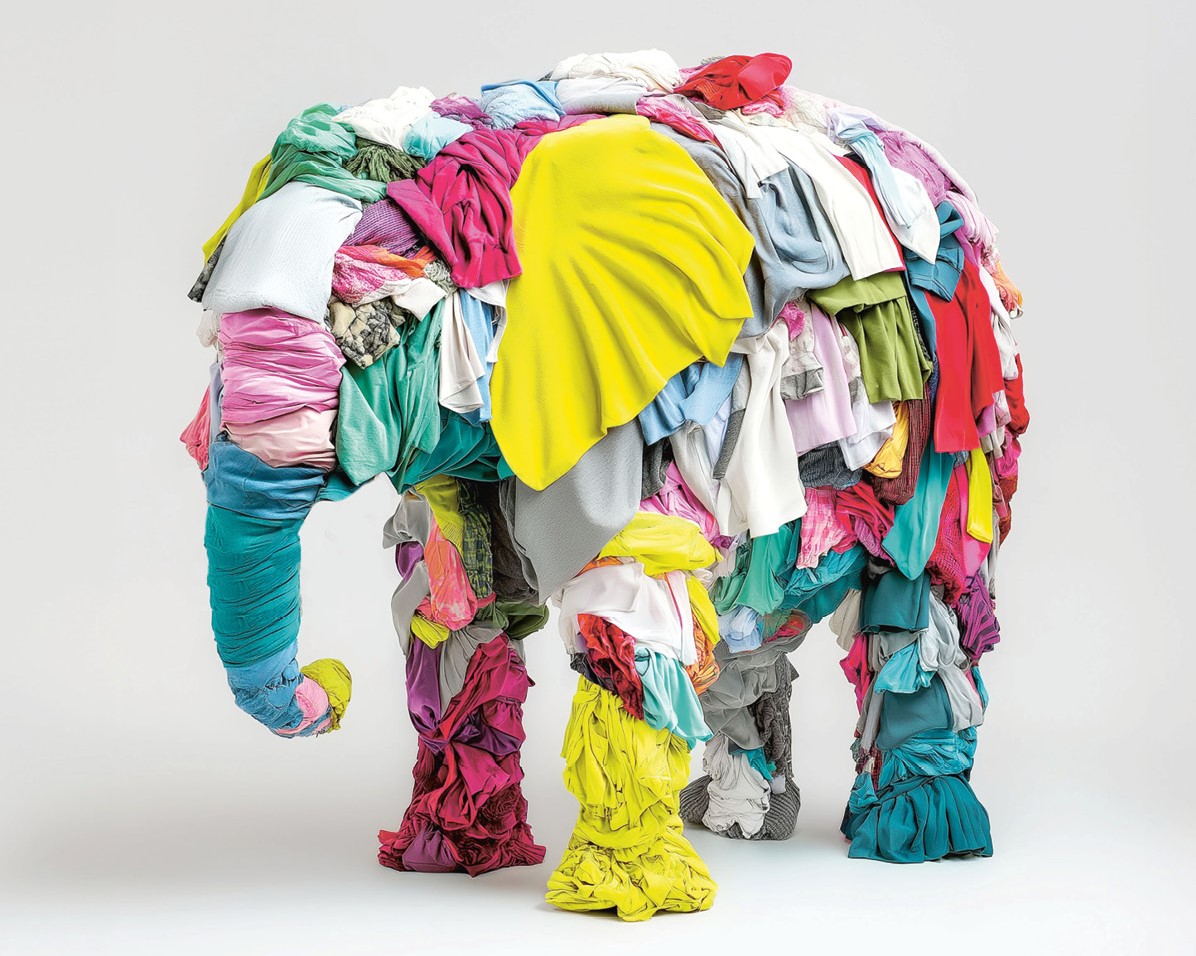

Pret-á-Porter

Across the globe, ninety-nine percent of discarded garments end up in landfills, but a French start-up is determined to change that. Reju’s goal is to turn waste into a resource and upend an outdated, linear industry. And it’s launched a cutting-edge textile-to-textile recycling facility in Frankfurt.

Dec 18, 2025

Tiny white granules slip through the fingers of Reju CEO Patrik Frisk. Hardly spectacular, but they represent the seeds of an ambitious industrial pivot. Reju’s mission is simple in principle but complex in execution: to manufacture new textiles from old ones at scale. Central to this effort is the recycling of polyester, a non-biodegradable synthetic polymer.

Reju’s broader ambition is to enable a circular economy for textiles worldwide. Its first step toward this goal is the “Regeneration Hub Zero” in Frankfurt. In October 2024, after less than a year of construction, the company inaugurated its pilot plant, which demonstrates how polyester garments are chemically broken down through depolymerization — a process that disassembles the polymer into its base monomers, which are then reassembled into new polyester. The company is planning to open industrial-scale Regeneration Hubs in the near future, capable of producing a thousand tons of recycled polyester annually. The result, the company claims, is a material with roughly half the carbon footprint of virgin polyester. The Frankfurt facility serves as proof that this process of chemistry can be indeed industrialized.

This article was published in issue 3-2025 of the Markets Germany Magazine. Read more articles of this issue here

Why Frankfurt?

Established in 2023, Reju is a subsidiary of Technip Energies, an engineering and technology firm employing over 17,000 people across 34 countries. The company could have located its first plant almost anywhere. It chose Frankfurt am Main — a nod not only to the city’s strategic location, but also to the broader appeal of the regional state of Hesse as a destination for innovation-driven businesses with a global mindset.

Frankfurt offered more than just a convenient location. It is also home to T.EN Zimmer, a polymer technology affiliate within the Technip Energies group. Reju also benefited from the region’s strong logistics infrastructure — its international airport, dense motorway network and high-speed rail links — and its geographic proximity to European markets. “Frankfurt’s central location supports our partnerships across Europe, where we’re working to build a circular textile system,” says the company.

Germany’s deep bench of technical talent and world-class research institutions also tipped the scales. Reju notes that access to engineering, materials science and sustainability expertise is crucial for ongoing innovation and scale. “This ecosystem is essential for advancing our recycling technology and scaling our impact.”

Equally compelling for Reju was the sheer volume of Germany’s secondary materials. With an estimated two to three million tons of textile waste generated annually, the country presents both a challenge and an opportunity. “Recycling options are still scarce,” says Carsten Ott of the regional development agency Hessen Trade & Invest. Demand, however, is growing. “Germany is a highly attractive market for recycled polyester,” Reju observes, citing ambitious sustainability targets, increasing appetite from brands and consumers and a favorable regulatory and industrial environment.

The Bottom Line

French company Reju is laying the groundwork for a circular textile economy with its state-of-the-art plant in Frankfurt. Polyester is the first material it will focus on recycling.

With a little help from some friends

Reju did not make the journey alone. Its relocation was facilitated by a coalition of public-sector partners, including Germany Trade & Invest, Hessen Trade & Invest and the Hessian Ministry of Economic Affairs. Together, they helped move the project from plan to pilot in under a year. “We bring relocation support and technology funding under one roof,” explains Ott. “That shortens timelines, reduces bureaucracy and accelerates results.”

Support starts at an early stage. Before a location is chosen, businesses receive market intelligence, assistance with site selection and advice on regulatory processes. Technical experts can be brought in at the outset to smooth the path from concept to commissioning. The state of Hesse’s support extended beyond advisory services. Reju also received a grant as part of its program to promote circular economy technologies. The scheme targets firms, both large and small, that deploy novel methods for reintegrating raw materials into industrial production. Funding typically ranges from EUR 500,000 to 1 million. “It’s a perfect fit,” says Ott.

Reju echoes the sentiment: “We’re grateful for the strong support from Germany Trade & Invest, Hessen Trade & Invest and the Hessian Ministry of Economic Affairs, which reflects the region’s commitment to sustainable innovation.” Initial batches of recycled polyester are now in production, with deliveries scheduled to begin in 2025.

REJU AT A GLANCE

CEO Patrik Frisk

Founded November 2023, Paris

Parent company Technip Energies

Mission Build a global circular system for textiles through textile-to-textile recycling

Technology VolCat, an IBM-developed depolymerization process

Pilot plant “Regeneration Hub Zero,” operational in Frankfurt since October 2024

Environmental impact Recycled polyester has approximately 50 percent lower CO₂ emissions than virgin material

Next steps A facility capable of processing 60,000 tons of used textiles annually is planned for the Netherlands by 2027